Omenala igwe anaghị agba nchara akụkụ ịgbado ọkụ ọrụ

Nkọwa ngwaahịa

ịgbado ọkụ na-eguzogide

Ịgbado ọkụ na-eguzogide bụ usoro ịgbado ọkụ nke a na-ejikọta workpiece na nrụgide site na electrode, na ọkụ eletrik na-etinye ya site na ikpo ọkụ ọkụ na-emepụta site na kọntaktị elu na n'akụkụ akụkụ nke nkwonkwo.Ịgbado ọkụ na-eguzogide bụ usoro ikpo ọkụ na-arụ ọrụ na steeti a wụrụ awụ ma ọ bụ rọba site na ọkụ eletrik na-agafe na elu kọntaktị na mpaghara ndị dị n'akụkụ.Enwere ụzọ ịgbado ọkụ anọ bụ isi, ya bụ ịgbado ọkụ ntụpọ, ịgbado ọkụ ọnụ, ịgbado ọkụ amụma na ịgbado ọkụ.

Carbon dioxide ịgbado ọkụ

Ihe mkpuchi ikuku nke carbon dioxide arc ịgbado ọkụ bụ carbon dioxide (mgbe ụfọdụ ngwakọta nke CO2 + Ar).A na-eji ya eme ihe maka ịgbado ọkụ n'aka.N'ihi mmetụta pụrụ iche nke thermal anụ ahụ Njirimara nke carbon dioxide gas, mgbe ị na-eji ot ịgbado ọkụ ike ọkọnọ, ọ gaghị ekwe omume na-etolite a guzozie eguzozie axial free mgbanwe site na-agbaze na metal na ịgbado ọkụ ọgwụgwụ waya ọgwụgwụ, nke na-achọkarị obere sekit na droplet necking. mgbawa.Ya mere, ma e jiri ya tụnyere MIG ịgbado ọkụ mgbanwe free, e nwere ihe nkusa.Ma ọ bụrụ na ojiji nke elu àgwà ịgbado ọkụ igwe, nri oke nke parameters, nwere ike nweta a nnọọ ike ịgbado ọkụ usoro, nke mere na spatter na-ebelata ka a kacha nta ogo.N'ihi ọnụ ala dị ala nke gas nchebe eji eme ihe, a na-emepụta weld nke ọma mgbe ị na-eji obere mgbanwe sekit, yana iji waya nwere deoxidizer nwere ike nweta na-enweghị ntụpọ n'ime ime nke nkwonkwo ịgbado ọkụ dị mma.Ya mere, usoro ịgbado ọkụ a aghọwo otu n'ime ụzọ ịgbado ọkụ kachasị mkpa maka ihe igwe ferrous.

Argon arc ịgbado ọkụ

Argon arc welding bụ teknụzụ ịgbado ọkụ na-eji argon gas dị ka gas na-echebe.A makwaara dị ka ịgbado ọkụ argon ahụ.Ọ bụ ịgafe gas nchebe argon gburugburu arc ịgbado ọkụ iji kewapụ ikuku n'èzí ebe ịgbado ọkụ ma gbochie oxidation nke ịgbado ọkụ ebe.

Teknụzụ ịgbado ọkụ nke Argon arc bụ dabere na ụkpụrụ nke ịgbado ọkụ eletrik nkịtị, na-eji nchekwa argon gas maka ihe ịgbado ọkụ ọla, site na elu ugbu a na ihe ịgbado ọkụ na-akwado ịgbado ọkụ n'ime ọdọ mmiri guzobe, na-eme ka igwe weld na weld ihe. metallurgy jikọtara ya na ụdị ịgbado ọkụ technology, na elu okpomọkụ agbaze ịgbado ọkụ na argon mgbe niile, na-eme ka weld ihe onwunwe enweghị ike ịkpọtụrụ oxygen na ikuku, Ya mere gbochie ọxịdashọn nke ịgbado ọkụ ihe onwunwe, otú i nwere ike weld igwe anaghị agba nchara, ígwè ígwè.

Mgbado ọkụ laser

Enwere ike nweta ịgbado ọkụ laser site na ọkụ laser na-aga n'ihu ma ọ bụ pulsed.Enwere ike kewaa ụkpụrụ nke ịgbado ọkụ laser n'ime ịgbado ọkụ ọkụ conduction na ịgbado ọkụ laser miri emi.Mgbe ike njupụta bụ ihe na-erughị 10-10 W / cm, ọ bụ okpomọkụ conduction ịgbado ọkụ, na ịgbado ọkụ omimi na ịgbado ọkụ ọsọ bụ ngwa ngwa.Mgbe ike njupụta dị ukwuu karịa 10 ~ 10 W / cm, metal elu bụ concave n'ime "oghere" n'okpuru omume nke okpomọkụ, na-akpụ miri fusion ịgbado ọkụ, nke nwere àgwà nke ngwa ngwa ịgbado ọkụ ọsọ na nnukwu ruru nke omimi ka obosara.

Ụkpụrụ nke ikpo ọkụ ọkụ ọkụ laser ịgbado ọkụ bụ: laser radieshon na-ekpo ọkụ n'elu ka a na-edozi, na elu okpomọkụ na-agbasa n'ime ime site okpomọkụ conduction.Site n'ịchịkwa akara laser dị ka obosara, ike, ike kacha elu na ugboro ugboro nke usu laser, a na-agbaze workpiece ma mepụta ọdọ mmiri gbazere.

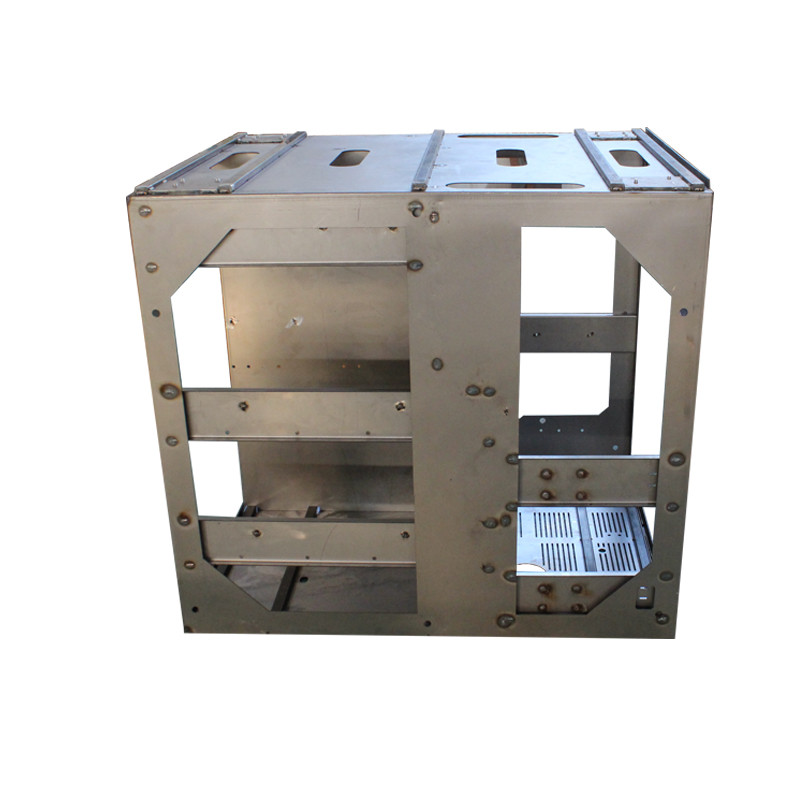

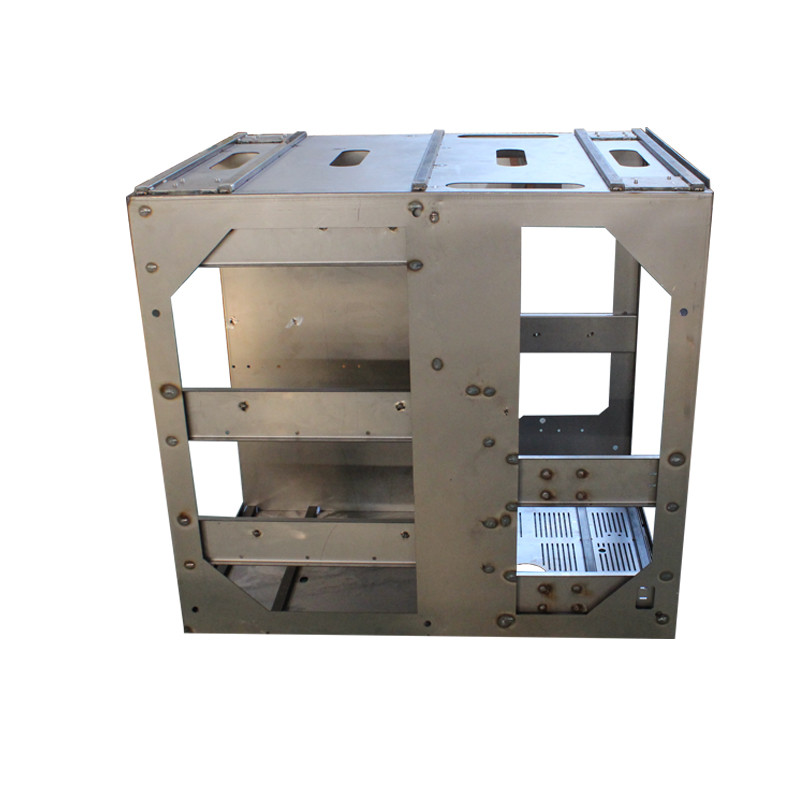

Lambert mpempe akwụkwọ metal nhazi ngwọta na-eweta.

Na afọ iri nke ahụmahụ na mba ọzọ ahia, anyị ipuiche na elu nkenke mpempe akwụkwọ metal nhazi akụkụ, laser ọnwụ, mpempe akwụkwọ ehulata, metal brackets, mpempe akwụkwọ metal chassis shells, chassis ike ọkọnọ housings, wdg Anyị bụ ndị ọkachamara dị iche iche n'elu agwọ ọrịa, brushing. , polishing, sandblasting, spraying, plating, nke nwere ike tinye n'ọrụ azụmahịa aghụghọ, ọdụ ụgbọ mmiri, àkwà mmiri, akụrụngwa, ụlọ, hotels, dị iche iche piping usoro, wdg Anyị nwere elu nhazi ngwá na ọkachamara teknuzu otu nke n'elu 60 ndị mmadụ na-enye elu. àgwà na ịrụ ọrụ nhazi nke ọma nye ndị ahịa anyị.Anyị na-enwe ike ịmepụta ihe mpempe akwụkwọ nke ụdị dị iche iche iji gboo mkpa ndị ahịa anyị zuru oke.Anyị na-emepe emepe mgbe niile ma na-emeziwanye usoro anyị iji hụ na ịdị mma na nnyefe, na anyị na-abụkarị "ndị ahịa lekwasịrị anya" iji nye ndị ahịa anyị ọrụ dị mma ma nyere ha aka ime nke ọma.Anyị na-atụ anya iwulite mmekọrịta ogologo oge na ndị ahịa anyị na mpaghara niile!